|

Timing: Weekend (6 Hrs/day, Saturday & Sunday) OR Weekday 3 Hrs/day, (Monday to Thursday) |

|

|

Topics |

Exercises |

|

Introduction to the workshop |

SIMATIC Family Overview |

|

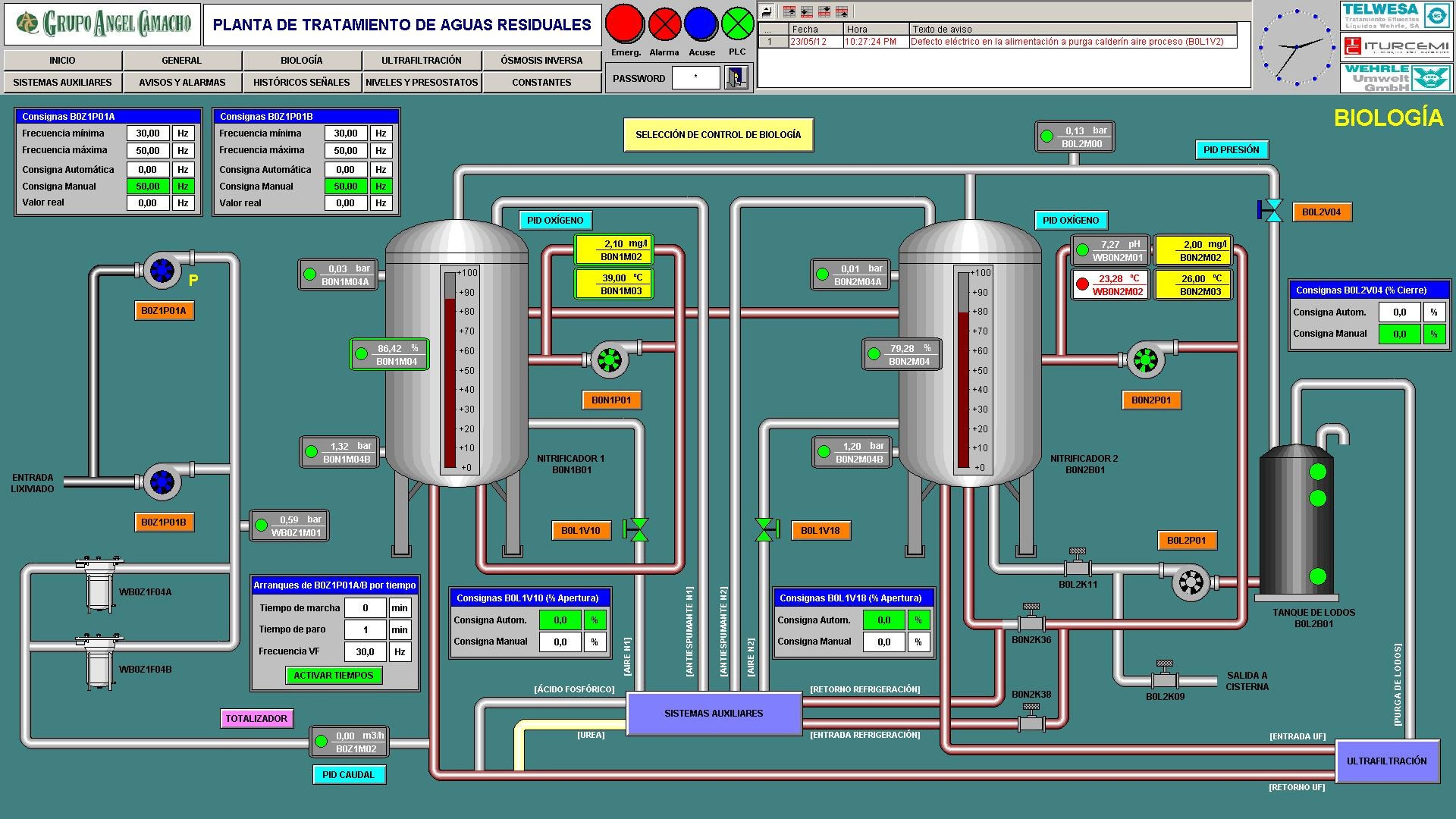

System overview 1.SCADA Introduction and Features2.Different SCADA software in market3.SIMATIC WinCC explorer and WinCC FlexibleSCADA Application license sizes |

Running Demo projects on SCADA and PLCs Multi plants project of PLC’s FBs and SCADA using advance techniques |

|

WinCC explorer

4.Creating a new Project5.Digital control in graphic designer with numeric Internal TagsStatic Text, graphic object, VB Script and C Script, input field, images libraries 6.Numeric Controls in Graphic designer with numeric Internal TagsInc/Dec Lib buttons, Display-Lib, Bar and Slide are grouped, Status Display, Status Display Text, Text List

|

Chapter 2: Exercise 1- Software environment

Chapter 2: Exercise 2~8 Digital controls using Internal Tags Chapter 2: Exercise 9- Summary of Exercise 1 to Exercise 8

Exercise 10~17 Numeric Controls using internal Tags

Exercise 18 ActiveX Control WinCC Gauge Control, WinCC Slider Control |

|

Timing: Weekend (6 Hrs/day, Saturday & Sunday) OR Weekday 3 Hrs/day, (Monday to Thursday) |

|

|

WinCC and S7-200 PLCs connection via OPC Connection

7.PC Access (Siemens OPC Server for S7-200 PLCs)8.Tag management9.Graphics controls for S7-200 PLC Project

|

Chapter 3: Project 1.1 “Room Temperature control project”-Exercise 3 of PLC course for S7-200 PLC

|

|

WinCC and S7-300/400 PLCs connection via MPI Connection |

Chapter 3: Project 1.2 “4 Way Traffic Lights Control and Monitoring Project” for S7-300 PLC.

|

|

Timing: Weekend (6 Hrs/day, Saturday & Sunday) OR Weekday 3 Hrs/day, (Monday to Thursday) |

|

|

Topics |

Exercises |

|

Animations in WinCC

10.Flow in a Pipe11.Tank Level Display12.Floating limit Switches ON/OFF Display in a tankSecurity & Access control in WinCC

13.Creating New Users14.Creating limits of the Users15.Login and Logout16.Access of different controlsMANU AND TOOL BAR Manu and Tools Bar for a project |

Chapter 4: Project 3.1 “Exercise 4.1 Blending Plant Project for S7-200 PLC

Project 3.2 “Adding security to Exercise 4.1 Blending Plant Project for S7-200 PLC

Project 3.3 “Adding Manu and Tool Bar to Exercise 4.1 Blending Plant Project for S7-200 PLC

|

|

ALARMS AND MASSAGES

17.Analog Alarms18.Alarms Classes19.Alarms massage Types20.Configurations of different alarms21.Creating Picture and controls for AlarmsDATA MASKING Communications with PLCs using full register and extracting individual bits |

Chapter-5: tutorial for Alarms by AAE

Chapter-6: VFD control project by AAE |

|

Timing: Weekend (6 Hrs/day, Saturday & Sunday) OR Weekday 3 Hrs/day, (Monday to Thursday) |

|

|

Topics |

Exercises |

|

COMMUNICATIONS

FACEPLATES IN WINCC

SCADA SCRIPT LANGUAGES

|

Chapter 6: Communications of Siemens PLC through Modbus Protocol

Chapter-6: VFD control project by AAE (Contd.)

Chapter-6: VFD control project by AAE(Contd.) |

|

REPORTS & CHARTS/GRAPHS

EFFICIENT

PROGRAMMING

Complete project development for HMI Panel |

Chapter-7 Temperature control using analog sensor

Chapter-8 Multi plant programming tutorial by AAE

Chapter-9 HMI Panel Projects i-e Blending Plant and packing control projects |